Agile vs. Lean Manufacturing in 2024: Choosing the Right Workforce Strategy with Quinn Vietnam Manpower

- trienkhaiweb

- 22 December, 2024

- 0 Comments

In the fast-paced world of manufacturing, staying competitive demands continuous adaptation and efficiency. Two methodologies, agile and lean manufacturing, have emerged as leading strategies to streamline production processes and maximize value. As a business leader, understanding the nuances between these approaches is crucial for choosing the right manpower solution and ensuring your company thrives. Quinn Vietnam Manpower, a specialist in providing top-tier workforce solutions, can help you navigate these complex decisions.

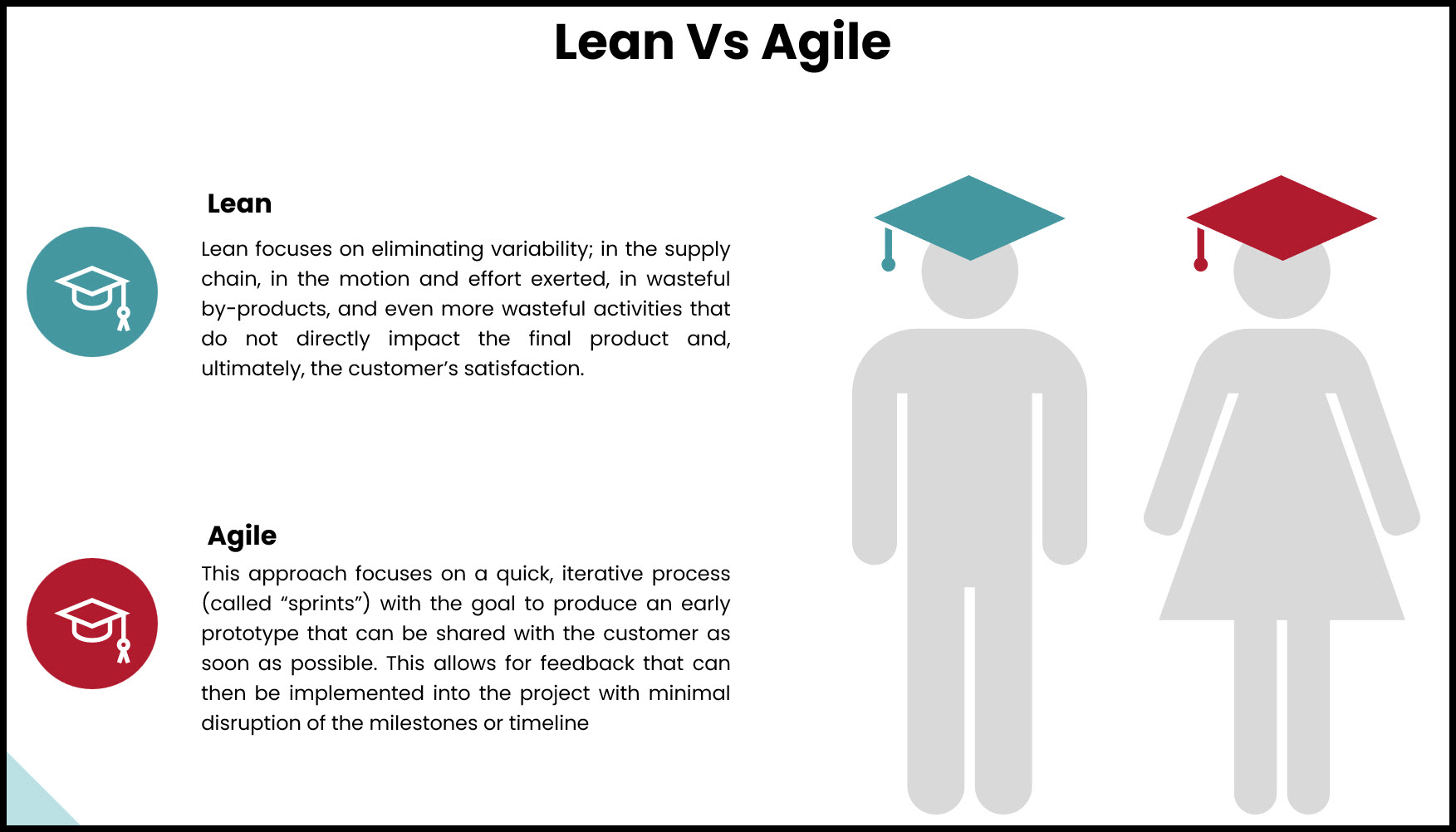

The Lean Manufacturing Model: A Deep Dive

Lean manufacturing is a systematic methodology aimed at eliminating waste and maximizing customer value. By continuously refining processes and optimizing resource utilization, lean manufacturing aims to achieve the highest level of efficiency.

Key Principles of Lean Manufacturing

-

Identifying and Eliminating Waste: Lean manufacturing meticulously identifies and eliminates any activities or resources that don’t directly contribute to customer value. This includes excess inventory, unnecessary motion, overproduction, and defects.

-

Continuous Improvement (Kaizen): Lean manufacturing emphasizes the ongoing pursuit of perfection. Employees at all levels are encouraged to identify areas for improvement and implement changes that enhance the production process.

-

Respect for People: Lean manufacturing recognizes the essential role employees play in the success of the organization. It fosters a culture of respect, collaboration, and empowerment, enabling workers to contribute their ideas and expertise.

Quinn Vietnam Manpower specializes in providing skilled workers who understand lean principles and can seamlessly integrate into your workforce to drive efficiency and reduce costs.

The Agile Manufacturing Model: Flexibility in Focus

Agile manufacturing is a dynamic approach that prioritizes flexibility and adaptability. By embracing change and fostering a culture of collaboration, agile manufacturing enables businesses to respond swiftly to evolving market conditions and customer demands.

Key Principles of Agile Manufacturing

-

Iterative Development: Agile manufacturing breaks down projects into smaller, manageable iterations. This allows for rapid feedback, continuous improvement, and quick adaptation to changing requirements.

-

Collaboration and Communication: Agile manufacturing relies heavily on effective collaboration and communication between cross-functional teams. By fostering a culture of transparency and open communication, agile teams can swiftly identify and resolve issues, ensuring a smooth production process.

-

Customer-Centricity: Agile manufacturing places a high value on customer feedback and satisfaction. By actively engaging with customers and incorporating their feedback into the development process, agile teams can deliver products and services that meet or exceed expectations.

Quinn Vietnam Manpower can help you source agile-minded professionals who excel in fast-paced environments, embrace change, and prioritize customer satisfaction.

Agile vs. Lean: Key Differences.

| Feature | Agile Manufacturing | Lean Manufacturing |

|---|---|---|

| Focus | Flexibility and Adaptability | Waste Reduction and Efficiency |

| Approach | Iterative and Non-linear | Linear and Process-Oriented |

| Production Planning | Demand-Driven | Forecast-Driven |

| Production Process | Changeable and Customizable | Standardized and Streamlined |

| Teamwork | Cross-Functional Collaboration | Continuous Improvement Teams |

| Communication | Open and Frequent | Structured and Problem-Solving |

Choosing the Right Path with Quinn Vietnam Manpower

Deciding between agile and lean manufacturing isn’t a one-size-fits-all decision. It depends on your company’s specific goals, industry, and market dynamics. Quinn Vietnam Manpower can assess your unique needs and provide tailored manpower solutions that align with your chosen methodology.

-

For Lean Manufacturing: Quinn Vietnam Manpower can provide skilled workers trained in lean principles, including waste reduction, process optimization, and continuous improvement.

-

For Agile Manufacturing: Quinn Vietnam Manpower can source adaptable professionals experienced in iterative development, cross-functional collaboration, and customer-centricity.

No matter which path you choose, Quinn Vietnam Manpower is dedicated to providing the right manpower to optimize your manufacturing processes and achieve success in today’s competitive landscape.

Related articles

Employee Empowerment with Quinn Vietnam Manpower

In today’s dynamic business landscape, organizations are increasingly recognizing the importance of employee empowerment as a key driver of success. Quinn Vietnam Manpower, a leading provider of manpower solutions in Vietnam, understands that empowered employees are more engaged, productive, and committed to organizational goals. This article delves into the concept of employee empowerment, exploring its…

Quinn Vietnam Manpower’s 5 Steps to Successful Coaching in 2025

In today’s dynamic business environment, maximizing your manpower’s potential is crucial for success. Effective coaching programs are key to unlocking this potential, fostering employee growth, and driving organizational performance. Quinn Vietnam Manpower, a leading provider of manpower solutions, presents a comprehensive guide to successful coaching in 2025. Whether you’re leading coaching sessions yourself or partnering…

Functional Skills: A Guide for Quinn Vietnam Manpower’s Workforce in 2025

In today’s competitive job market, possessing strong functional skills is more critical than ever. For Quinn Vietnam Manpower, equipping our manpower resources with these essential skills is key to their success and the success of our partner businesses. This comprehensive guide explores the importance of functional skills, particularly in Math and English, and how Quinn…

Level Up Your Workforce: Gamification Strategies for Quinn Vietnam Manpower

In the competitive landscape of Vietnam’s manpower industry, attracting, engaging, and retaining top talent is more critical than ever. Quinn Vietnam Manpower recognizes the power of innovative solutions, and gamification is emerging as a game-changer in the realm of human resources. By integrating game mechanics and elements into various HR processes, Quinn Vietnam Manpower can…

3 Communication Skills Every Manager Needs to Thrive

In today’s rapidly evolving business landscape, effective communication skills are more critical than ever for managers. Whether you’re a seasoned leader or newly promoted, honing your communication abilities can significantly impact your team’s performance, morale, and overall success. This article delves into three essential communication skills every manager needs to master in 2025 and highlights…

Harnessing the Power of Insights with Quinn Vietnam Manpower

In the dynamic landscape of 2025, where businesses face unprecedented challenges and opportunities, the ability to gain profound insights is more critical than ever. For project management (PM) in Vietnam, this rings especially true. Quinn Vietnam Manpower, a leading provider of manpower solutions, recognizes the crucial role of insights in driving project effectiveness and organizational…