The Future of Lean Supply Chain: How Quinn Vietnam Manpower is Leveraging Technology to Optimize Workforce Solutions

- trienkhaiweb

- 14 December, 2024

- 0 Comments

In today’s rapidly evolving business landscape, lean supply chain methodologies have emerged as a critical focus for companies seeking to optimize their operations and enhance customer value. With the advent of Industry 4.0 and the integration of advanced technologies, the potential for lean supply chain transformation has never been greater.

This article explores how Quinn Vietnam Manpower, a leading provider of manpower solutions, is harnessing the power of technology to revolutionize lean supply chain management, ensuring efficient and effective workforce solutions for businesses across various industries.

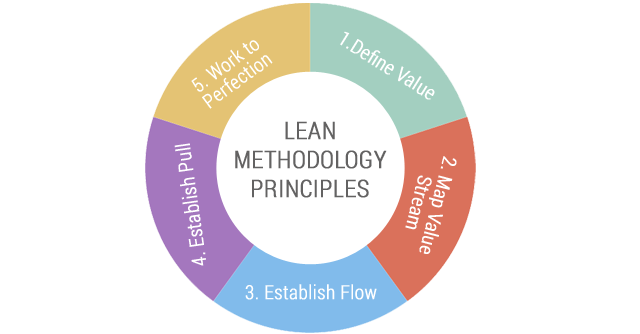

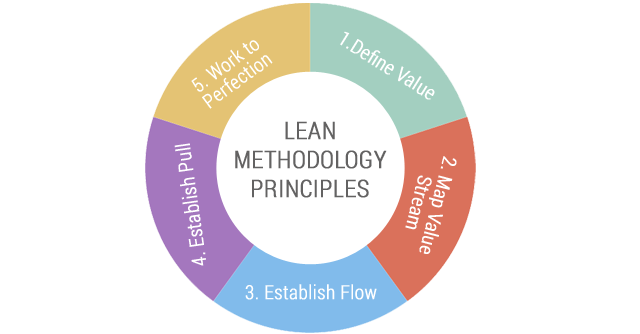

Understanding Lean Supply Chain Principles

At its core, a lean supply chain is an approach to supply chain management that emphasizes the elimination of waste and the maximization of value for customers. This methodology, inspired by the Toyota Production System, entails the integration of lean principles into supply chain processes to eliminate non-value-added activities and drive cost reductions.

The primary objective of lean supply chain management is to streamline the flow of goods and information across the entire supply chain, from suppliers to end customers. This involves fostering collaboration and communication among all stakeholders, including suppliers, manufacturers, distributors, retailers, and customers.

By embracing lean supply chain principles, businesses can achieve significant improvements in efficiency, productivity, and customer satisfaction.

The Role of Technology in Lean Supply Chain Optimization

Technology plays a pivotal role in enabling lean supply chain optimization. By leveraging advanced tools and systems, businesses can unlock a wide range of benefits, including:

- Improved Efficiency and Productivity: Automation, real-time inventory tracking, and production schedule optimization are just a few examples of how technology can streamline operations and reduce waste, leading to increased efficiency and productivity.

- Enhanced Visibility and Transparency: Technology provides real-time tracking and monitoring capabilities, enabling businesses to gain comprehensive visibility into their supply chain processes. This allows for the identification of bottlenecks, proactive issue resolution, and improved customer satisfaction.

- Reduced Costs and Waste: Data analytics plays a crucial role in identifying inefficiencies and enabling data-driven decision-making. Additionally, automation and digitalization can minimize manual labor requirements, resulting in cost reductions and waste minimization.

- Better Risk Management: Real-time data and insights empower businesses to identify and mitigate potential risks and vulnerabilities proactively. This reduces the likelihood of disruptions and delays, ensuring supply chain resilience.

- Enhanced Customer Experience: Real-time shipment tracking, accurate delivery estimates, and personalized product recommendations are examples of how technology can elevate the customer experience.

Quinn Vietnam Manpower: Pioneering Lean Supply Chain with Technology

Quinn Vietnam Manpower recognizes the transformative potential of technology in optimizing lean supply chains, particularly in the realm of manpower solutions. The company has invested in cutting-edge technologies to streamline recruitment, onboarding, training, and workforce management processes.

By leveraging automation and digital platforms, Quinn Vietnam Manpower has significantly reduced the time and effort required to match qualified workers with suitable job opportunities. Real-time data analytics enable the company to identify skill gaps and provide targeted training programs, ensuring that the workforce is equipped with the necessary expertise to meet industry demands.

Furthermore, Quinn Vietnam Manpower’s commitment to lean principles extends to its internal operations. By eliminating redundancies and optimizing processes, the company has achieved cost savings and improved operational efficiency, which translates to greater value for its clients.

Case Studies of Successful Lean Supply Chain Implementations

Several industry leaders have demonstrated the remarkable results that can be achieved by integrating technology into lean supply chain strategies.

- Toyota Motor Corporation: Toyota’s renowned production system, which emphasizes waste reduction and continuous improvement, has been enhanced by technology. The company utilizes data analytics to optimize production schedules and inventory levels, while IoT devices provide real-time supply chain monitoring.

- Amazon.com, Inc.: Amazon’s vast logistics network relies heavily on automation and robotics to streamline warehouse operations. Data analytics further optimizes delivery routes and inventory management, contributing to cost reductions and improved customer satisfaction.

- Procter & Gamble Co.: P&G leverages data analytics for real-time supply chain monitoring and proactive issue resolution. Additionally, the company employs automation to streamline manufacturing processes and blockchain technology to enhance transparency and traceability.

- Walmart Inc.: Walmart utilizes data analytics to optimize inventory levels and product placement, resulting in improved efficiency and reduced waste. IoT devices enable real-time monitoring of the supply chain, while automation streamlines warehouse logistics.

The Future of Lean Supply Chain with Technology

The future of lean supply chain management is undeniably intertwined with technological advancements. As technology continues to evolve, businesses can expect to see further growth opportunities, increased competition, and the emergence of new business models.

- Growth Opportunities: Advancements in technology will unlock greater levels of efficiency, productivity, and customer satisfaction. Businesses can explore new markets and expand their reach, fueled by technological innovation.

- Increased Competition and Innovation: The widespread adoption of technology will intensify competition, driving innovation and the development of new solutions to gain a competitive advantage.

- Evolution of Job Roles and Skills: New technologies will reshape job roles and skill requirements within the supply chain domain. Data analysis, digital literacy, and problem-solving skills will become increasingly important.

- New Business Models: Technology will enable the creation of novel business models, such as subscription-based services, the sharing economy, and personalized offerings. Collaboration between businesses, suppliers, and customers will give rise to new revenue streams.

Conclusion

The integration of technology into lean supply chain methodologies is not merely a trend but a necessity for businesses seeking to thrive in the digital age. Quinn Vietnam Manpower’s commitment to leveraging technology to optimize workforce solutions exemplifies the future of lean supply chain management.

By embracing technological advancements, businesses can unlock unprecedented levels of efficiency, productivity, and customer satisfaction, ultimately leading to sustainable growth and success in an increasingly competitive global market. As we move forward, the continued evolution of technology promises to reshape the landscape of lean supply chain management, offering exciting possibilities for businesses that are willing to adapt and innovate.

Related articles

Employee Empowerment with Quinn Vietnam Manpower

In today’s dynamic business landscape, organizations are increasingly recognizing the importance of employee empowerment as a key driver of success. Quinn Vietnam Manpower, a leading provider of manpower solutions in Vietnam, understands that empowered employees are more engaged, productive, and committed to organizational goals. This article delves into the concept of employee empowerment, exploring its…

Quinn Vietnam Manpower’s 5 Steps to Successful Coaching in 2025

In today’s dynamic business environment, maximizing your manpower’s potential is crucial for success. Effective coaching programs are key to unlocking this potential, fostering employee growth, and driving organizational performance. Quinn Vietnam Manpower, a leading provider of manpower solutions, presents a comprehensive guide to successful coaching in 2025. Whether you’re leading coaching sessions yourself or partnering…

Functional Skills: A Guide for Quinn Vietnam Manpower’s Workforce in 2025

In today’s competitive job market, possessing strong functional skills is more critical than ever. For Quinn Vietnam Manpower, equipping our manpower resources with these essential skills is key to their success and the success of our partner businesses. This comprehensive guide explores the importance of functional skills, particularly in Math and English, and how Quinn…

Level Up Your Workforce: Gamification Strategies for Quinn Vietnam Manpower

In the competitive landscape of Vietnam’s manpower industry, attracting, engaging, and retaining top talent is more critical than ever. Quinn Vietnam Manpower recognizes the power of innovative solutions, and gamification is emerging as a game-changer in the realm of human resources. By integrating game mechanics and elements into various HR processes, Quinn Vietnam Manpower can…

3 Communication Skills Every Manager Needs to Thrive

In today’s rapidly evolving business landscape, effective communication skills are more critical than ever for managers. Whether you’re a seasoned leader or newly promoted, honing your communication abilities can significantly impact your team’s performance, morale, and overall success. This article delves into three essential communication skills every manager needs to master in 2025 and highlights…

Harnessing the Power of Insights with Quinn Vietnam Manpower

In the dynamic landscape of 2025, where businesses face unprecedented challenges and opportunities, the ability to gain profound insights is more critical than ever. For project management (PM) in Vietnam, this rings especially true. Quinn Vietnam Manpower, a leading provider of manpower solutions, recognizes the crucial role of insights in driving project effectiveness and organizational…