Additive Manufacturing Is The Future of Manufacturing

- trienkhaiweb

- 17 February, 2025

- 0 Comments

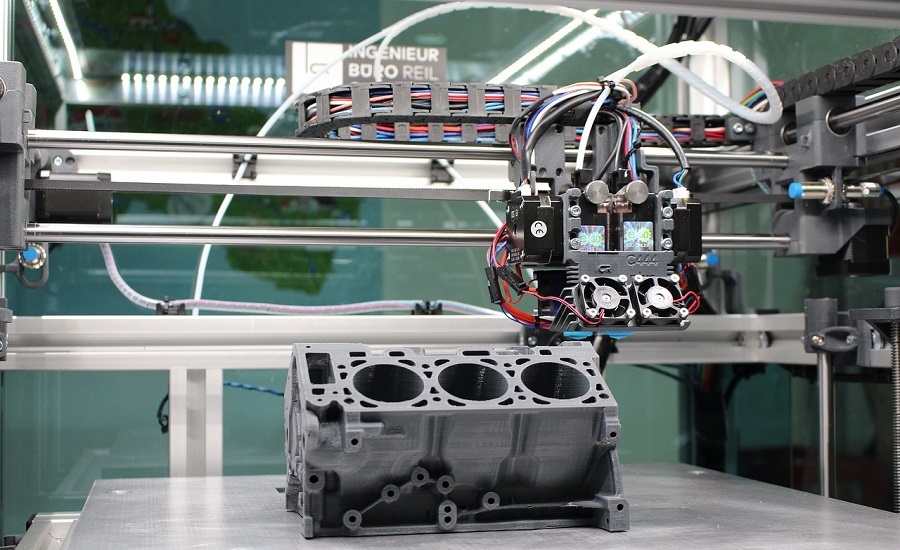

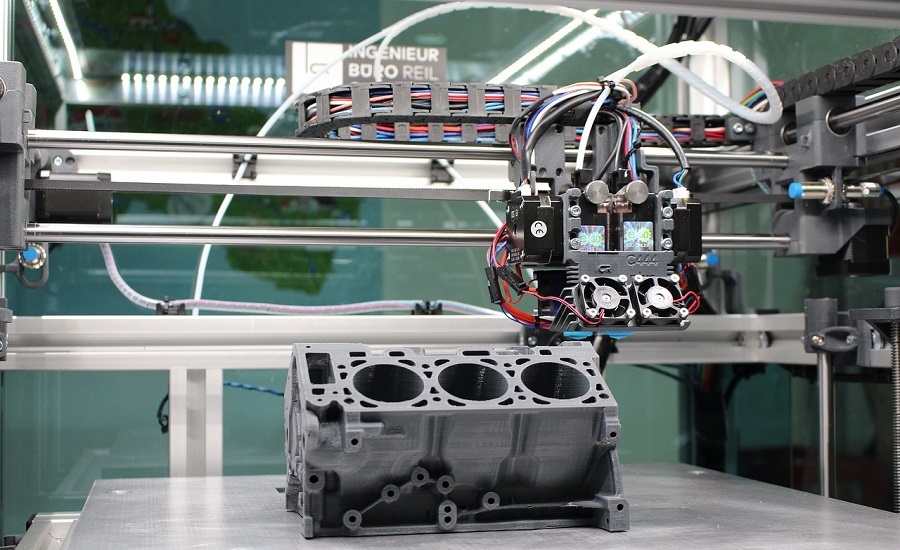

Additive manufacturing, more commonly known as 3D printing, is rapidly transforming the manufacturing landscape. This cutting-edge technology empowers businesses to create complex designs, accelerate production processes, and optimize resource utilization. In this article, we’ll explore the fundamentals of additive manufacturing, delve into its diverse applications, and examine how Quinn Vietnam Manpower is harnessing its potential to drive innovation and efficiency in 2025.

What is Additive Manufacturing?

Additive manufacturing is a revolutionary process that constructs three-dimensional objects by meticulously adding layers of material, one atop another, until the final form is realized. Unlike traditional subtractive manufacturing methods, which involve removing material from a solid block, additive manufacturing builds objects from the ground up, offering unparalleled design freedom and precision.

This digital fabrication technique empowers manufacturers to produce intricate geometries and bespoke designs with ease. By leveraging computer-aided design (CAD) software, intricate blueprints are translated into reality, layer by delicate layer. This process opens up a world of possibilities for industries seeking to push the boundaries of product design and functionality.

Types of Additive Manufacturing

The realm of additive manufacturing encompasses a variety of technologies, each with its own unique strengths and applications. Some of the most prevalent types include:

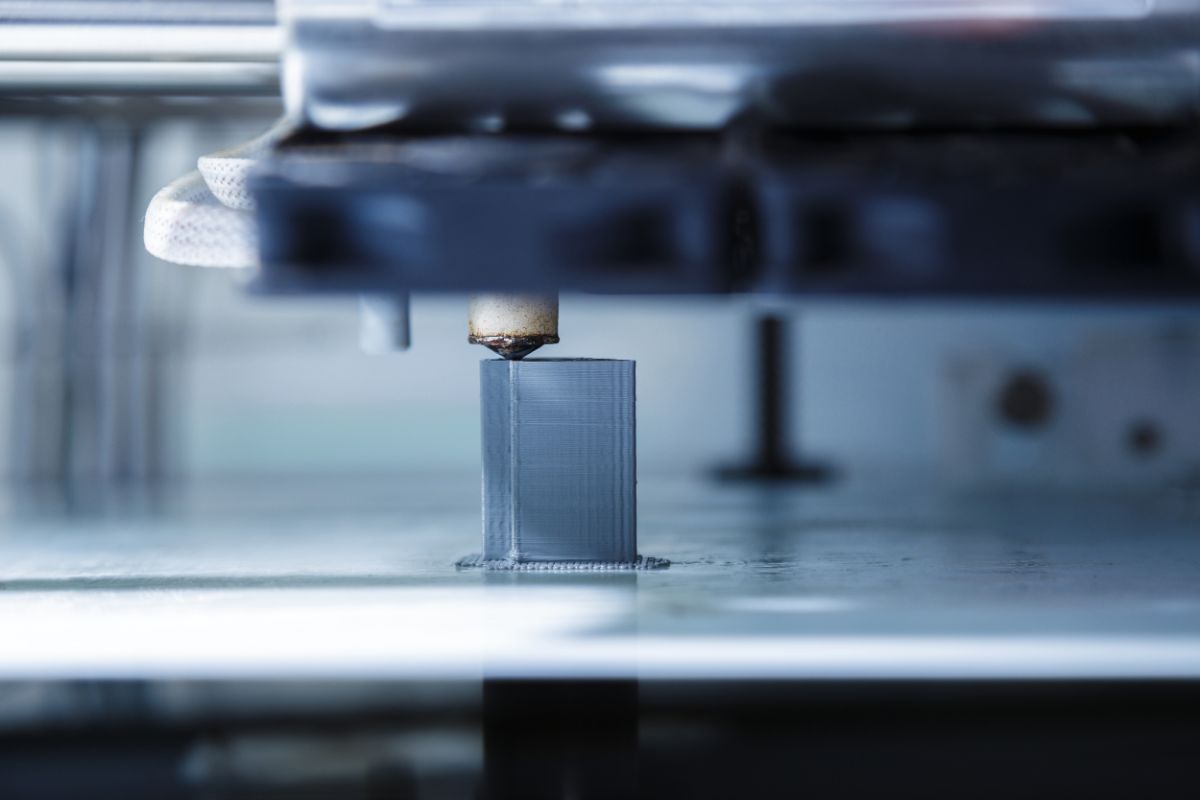

- Fused Deposition Modeling (FDM): This widely adopted technique involves extruding a heated thermoplastic filament through a nozzle, building objects layer by layer as the material cools and solidifies. FDM is renowned for its versatility and cost-effectiveness, making it a popular choice for prototyping and small-scale production.

- Stereolithography (SLA): SLA employs a UV laser to precisely cure liquid resin, creating highly detailed and intricate objects with exceptional surface quality. This technology finds extensive use in industries demanding precision and accuracy, such as dentistry, jewelry making, and medical device manufacturing.

- Selective Laser Sintering (SLS): SLS utilizes a high-powered laser to fuse powdered material, such as nylon or metal, into a solid mass. This method excels at producing durable and functional prototypes and end-use parts with complex geometries and intricate internal structures.

- Digital Light Processing (DLP): Similar to SLA, DLP employs a projector to cure liquid resin, but instead of tracing the object layer by layer, it projects an entire layer at once, significantly accelerating the printing process. DLP is particularly well-suited for producing small, intricate objects with high resolution and accuracy.

Advantages of Additive Manufacturing

Additive manufacturing offers a compelling array of advantages over traditional manufacturing processes, making it an increasingly attractive option for businesses across various industries:

- Unleashing Design Freedom: Additive manufacturing empowers designers to break free from the constraints of traditional manufacturing, enabling the creation of complex geometries and organic shapes that were previously impossible to achieve. This design freedom fosters innovation and allows for the development of products with enhanced functionality and aesthetics.

- Cost-Effective Production: While the initial investment in additive manufacturing equipment can be significant, the long-term cost benefits can be substantial. By reducing material waste, minimizing tooling costs, and streamlining production processes, additive manufacturing can lead to significant cost savings, particularly for low-volume production runs and highly customized products.

- Accelerated Prototyping: Additive manufacturing facilitates rapid prototyping, allowing businesses to quickly iterate and refine designs before committing to mass production. This accelerated development cycle reduces lead times, minimizes costly errors, and enables faster time-to-market for new products.

- Mass Customization: Additive manufacturing enables mass customization, allowing businesses to cater to individual customer needs and preferences without incurring exorbitant costs. This capability opens up new markets and allows businesses to offer personalized products that meet the unique demands of each customer.

- Reduced Environmental Impact: Additive manufacturing promotes sustainability by minimizing material waste and reducing energy consumption compared to traditional manufacturing methods. Additionally, the ability to produce parts on demand and closer to the point of need reduces transportation costs and associated environmental impacts.

Quinn Vietnam Manpower: Pioneering Additive Manufacturing in 2025

Quinn Vietnam Manpower, a leading provider of manpower solutions, recognizes the transformative potential of additive manufacturing and is actively integrating this technology into its operations in 2025. By embracing additive manufacturing, Quinn Vietnam Manpower is driving innovation, enhancing efficiency, and creating new opportunities for its clients and workforce.

Here’s how Quinn Vietnam Manpower is leveraging additive manufacturing:

- Workforce Training and Development: Quinn Vietnam Manpower is committed to equipping its workforce with the skills and knowledge necessary to thrive in the era of additive manufacturing. Through comprehensive training programs, employees are gaining expertise in 3D printing technologies, design software, and material science. This investment in human capital ensures that Quinn Vietnam Manpower remains at the forefront of the additive manufacturing revolution.

- Talent Acquisition and Placement: Quinn Vietnam Manpower specializes in identifying and placing highly skilled professionals in the field of additive manufacturing. By understanding the unique talent needs of this rapidly evolving industry, Quinn Vietnam Manpower connects businesses with the right people to drive their additive manufacturing initiatives forward.

- Industry Partnerships and Collaboration: Quinn Vietnam Manpower actively collaborates with leading companies and research institutions in the additive manufacturing space. These partnerships foster knowledge sharing, drive innovation, and ensure that Quinn Vietnam Manpower remains at the cutting edge of industry best practices.

- Promoting Additive Manufacturing Adoption: Quinn Vietnam Manpower is committed to raising awareness about the benefits of additive manufacturing and promoting its adoption across various industries. Through workshops, seminars, and industry events, Quinn Vietnam Manpower is educating businesses about the transformative potential of this technology and helping them integrate it into their operations.

Applications of Additive Manufacturing in 2025

Additive manufacturing is permeating a vast array of industries, revolutionizing product development and production processes. Here are some key applications of additive manufacturing in 2025:

- Aerospace and Defense: The aerospace and defense industries are leveraging additive manufacturing to produce lightweight, high-performance components with complex geometries. From intricate engine parts to customized aircraft components, additive manufacturing enables the creation of parts optimized for weight, strength, and functionality.

- Automotive: The automotive industry is utilizing additive manufacturing to accelerate prototyping, produce customized parts, and create tooling with reduced lead times and costs. This technology is particularly valuable for producing complex components, such as engine manifolds and intricate interior parts, with enhanced design freedom and functionality.

- Healthcare: Additive manufacturing is revolutionizing healthcare by enabling the creation of patient-specific implants, prosthetics, and medical devices. This technology allows for the precise customization of medical solutions, improving patient outcomes and quality of life. Additionally, additive manufacturing is used to create surgical models and guides, aiding in pre-operative planning and enhancing surgical precision.

- Architecture and Construction: The architecture and construction industry is exploring the potential of additive manufacturing to create complex building components, customized facades, and intricate architectural details. This technology offers new possibilities for sustainable construction by enabling the use of recycled and bio-based materials.

- Consumer Products: Additive manufacturing is empowering businesses to create customized consumer products, ranging from personalized jewelry and fashion accessories to bespoke footwear and sporting goods. This technology allows consumers to express their individuality and obtain products tailored to their specific needs and preferences.

The Future of Additive Manufacturing with Quinn Vietnam Manpower

As additive manufacturing continues to evolve, Quinn Vietnam Manpower is poised to play a pivotal role in shaping its future. By investing in workforce development, fostering industry partnerships, and promoting the adoption of this transformative technology, Quinn Vietnam Manpower is empowering businesses to harness the full potential of additive manufacturing.

In 2025 and beyond, Quinn Vietnam Manpower will continue to be a driving force in the additive manufacturing revolution, connecting businesses with the talent and resources they need to succeed in this dynamic landscape. With a commitment to innovation and a focus on client success, Quinn Vietnam Manpower is paving the way for a future where additive manufacturing unlocks new possibilities and drives unprecedented growth across industries.

Related articles

Employee Empowerment with Quinn Vietnam Manpower

In today’s dynamic business landscape, organizations are increasingly recognizing the importance of employee empowerment as a key driver of success. Quinn Vietnam Manpower, a leading provider of manpower solutions in Vietnam, understands that empowered employees are more engaged, productive, and committed to organizational goals. This article delves into the concept of employee empowerment, exploring its…

Quinn Vietnam Manpower’s 5 Steps to Successful Coaching in 2025

In today’s dynamic business environment, maximizing your manpower’s potential is crucial for success. Effective coaching programs are key to unlocking this potential, fostering employee growth, and driving organizational performance. Quinn Vietnam Manpower, a leading provider of manpower solutions, presents a comprehensive guide to successful coaching in 2025. Whether you’re leading coaching sessions yourself or partnering…

Functional Skills: A Guide for Quinn Vietnam Manpower’s Workforce in 2025

In today’s competitive job market, possessing strong functional skills is more critical than ever. For Quinn Vietnam Manpower, equipping our manpower resources with these essential skills is key to their success and the success of our partner businesses. This comprehensive guide explores the importance of functional skills, particularly in Math and English, and how Quinn…

Level Up Your Workforce: Gamification Strategies for Quinn Vietnam Manpower

In the competitive landscape of Vietnam’s manpower industry, attracting, engaging, and retaining top talent is more critical than ever. Quinn Vietnam Manpower recognizes the power of innovative solutions, and gamification is emerging as a game-changer in the realm of human resources. By integrating game mechanics and elements into various HR processes, Quinn Vietnam Manpower can…

3 Communication Skills Every Manager Needs to Thrive

In today’s rapidly evolving business landscape, effective communication skills are more critical than ever for managers. Whether you’re a seasoned leader or newly promoted, honing your communication abilities can significantly impact your team’s performance, morale, and overall success. This article delves into three essential communication skills every manager needs to master in 2025 and highlights…

Harnessing the Power of Insights with Quinn Vietnam Manpower

In the dynamic landscape of 2025, where businesses face unprecedented challenges and opportunities, the ability to gain profound insights is more critical than ever. For project management (PM) in Vietnam, this rings especially true. Quinn Vietnam Manpower, a leading provider of manpower solutions, recognizes the crucial role of insights in driving project effectiveness and organizational…