Optimizing Manpower with Automated Production Lines

- trienkhaiweb

- 16 June, 2025

- 0 Comments

As we move towards 2025, the manufacturing industry continues to embrace automation to enhance efficiency, productivity, and product quality. Quinn Vietnam Manpower recognizes the transformative potential of automated production lines in optimizing manpower and driving business growth. This comprehensive guide explores the benefits, applications, and key considerations for implementing automated production lines in the modern manufacturing landscape.

What is an Automated Production Line?

An automated production line is a sophisticated system of interconnected machines and equipment that work in sequence to perform manufacturing tasks with minimal human intervention. These lines are controlled by computerized systems and robotics, enabling precise and efficient production processes. By automating repetitive and labor-intensive tasks, manufacturers can optimize their manpower, reduce errors, and improve overall productivity.

Key Benefits of Automated Production Lines:

- Increased Productivity: Automation significantly increases production output by enabling continuous operation and faster cycle times.

- Enhanced Quality: Automated systems perform tasks with precision and consistency, reducing errors and improving product quality.

- Improved Safety: Automation minimizes the need for human involvement in hazardous tasks, improving workplace safety.

- Reduced Labor Costs: By automating tasks, manufacturers can reduce their reliance on manual labor, leading to cost savings.

- Increased Flexibility: Modern automated lines can be easily reconfigured to accommodate different product variations and production demands.

- Data-Driven Optimization: Automated systems generate valuable data that can be used to analyze performance, identify bottlenecks, and optimize production processes.

Popular Types of Automated Production Lines

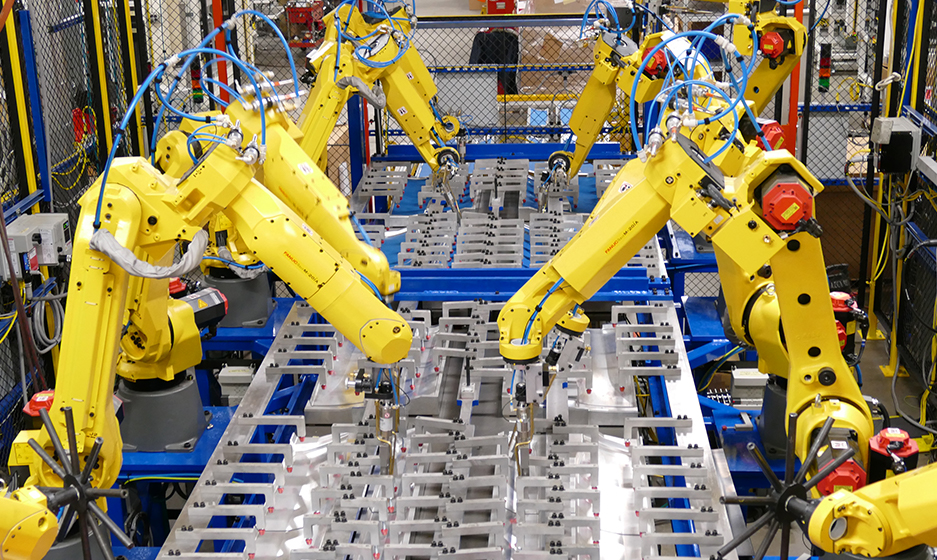

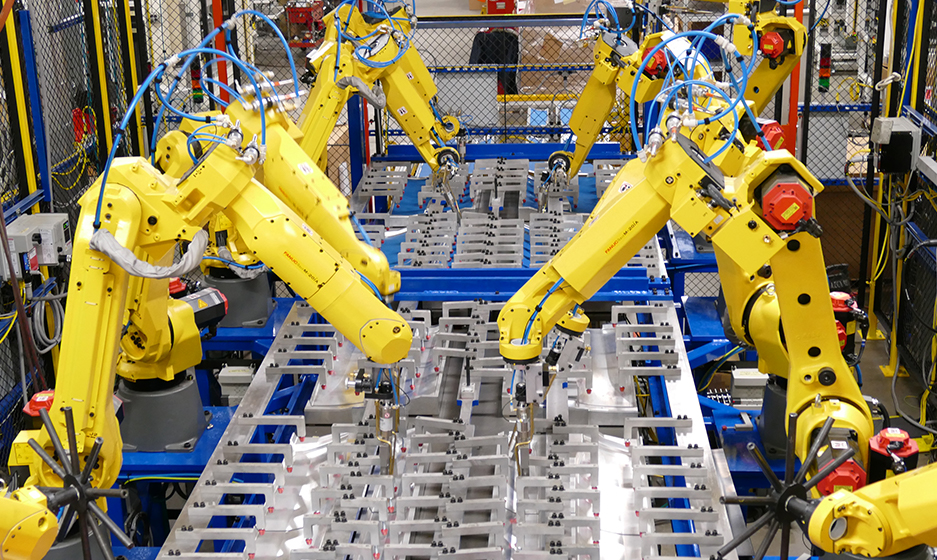

Automated production lines are versatile and can be adapted to various manufacturing processes. Some popular applications include:

- Automated Assembly Lines:

Widely used in industries like electronics, automotive, and consumer goods, automated assembly lines utilize robotic arms and specialized equipment to assemble components with high precision and speed. This optimizes manpower by freeing human workers from repetitive tasks and allowing them to focus on more complex operations.

- Automated Welding and Painting Lines:

In the metal fabrication industry, automated welding and painting lines ensure consistent quality, improve safety, and increase efficiency. Robots perform welding and painting tasks with precision, minimizing errors and ensuring uniform finishes. This not only optimizes manpower but also protects workers from hazardous fumes and repetitive motions.

- Automated Packaging Lines:

Automated packaging lines streamline the packaging process, improving efficiency and reducing waste. These lines can perform various tasks, such as filling, sealing, labeling, and palletizing, with minimal human intervention. This optimizes manpower by automating repetitive packaging tasks and allowing workers to focus on quality control and supervision.

- Automated Filling Lines:

Commonly used in the food and beverage industry, automated filling lines ensure accurate and consistent filling of products. These lines can handle various liquids and pastes, maintaining precise fill volumes and minimizing waste. This optimizes manpower by automating the filling process and ensuring product uniformity.

Quinn Vietnam Manpower’s Role in Automated Production

Quinn Vietnam Manpower recognizes that the successful implementation of automated production lines requires skilled manpower to operate, maintain, and optimize these systems. We provide comprehensive manpower solutions to support manufacturers in their automation journey:

- Skilled Technicians and Engineers: We recruit and place qualified technicians and engineers with expertise in automation technologies, robotics, and control systems.

- Training and Development: We offer training programs to upskill the existing manpower and equip them with the necessary skills to operate and maintain automated production lines.

- Manpower Outsourcing: We provide flexible manpower solutions to meet the fluctuating demands of automated production environments.

- Consulting and Support: Our experts offer guidance on automation strategies, manpower planning, and process optimization.

By partnering with Quinn Vietnam Manpower, manufacturers can access the skilled manpower they need to successfully implement and manage automated production lines, maximizing their return on investment and achieving their production goals.

Key Considerations for Implementing Automated Production Lines

While automated production lines offer significant benefits, manufacturers should consider the following factors before implementation:

- Investment Costs: Automation requires significant upfront investment in equipment, software, and integration.

- Production Volume: Automation is most effective for high-volume production where the benefits of increased efficiency and reduced labor costs can be maximized.

- Product Complexity: The complexity of the product and the manufacturing process will influence the type and level of automation required.

- Manpower Requirements: While automation reduces the need for manual labor, skilled manpower is still essential for operating, maintaining, and optimizing automated systems.

- Flexibility and Adaptability: Choose automation solutions that can be easily reconfigured to accommodate future product variations and production demands.

Conclusion

Automated production lines are transforming the manufacturing industry, enabling increased efficiency, productivity, and product quality. Quinn Vietnam Manpower is committed to supporting manufacturers in their automation journey by providing skilled manpower, training, and consulting services. By embracing automation and optimizing their manpower, manufacturers can stay competitive in the evolving global market and achieve sustainable growth.

Related articles

Employee Empowerment with Quinn Vietnam Manpower

In today’s dynamic business landscape, organizations are increasingly recognizing the importance of employee empowerment as a key driver of success. Quinn Vietnam Manpower, a leading provider of manpower solutions in Vietnam, understands that empowered employees are more engaged, productive, and committed to organizational goals. This article delves into the concept of employee empowerment, exploring its…

Quinn Vietnam Manpower’s 5 Steps to Successful Coaching in 2025

In today’s dynamic business environment, maximizing your manpower’s potential is crucial for success. Effective coaching programs are key to unlocking this potential, fostering employee growth, and driving organizational performance. Quinn Vietnam Manpower, a leading provider of manpower solutions, presents a comprehensive guide to successful coaching in 2025. Whether you’re leading coaching sessions yourself or partnering…

Functional Skills: A Guide for Quinn Vietnam Manpower’s Workforce in 2025

In today’s competitive job market, possessing strong functional skills is more critical than ever. For Quinn Vietnam Manpower, equipping our manpower resources with these essential skills is key to their success and the success of our partner businesses. This comprehensive guide explores the importance of functional skills, particularly in Math and English, and how Quinn…

Level Up Your Workforce: Gamification Strategies for Quinn Vietnam Manpower

In the competitive landscape of Vietnam’s manpower industry, attracting, engaging, and retaining top talent is more critical than ever. Quinn Vietnam Manpower recognizes the power of innovative solutions, and gamification is emerging as a game-changer in the realm of human resources. By integrating game mechanics and elements into various HR processes, Quinn Vietnam Manpower can…

3 Communication Skills Every Manager Needs to Thrive

In today’s rapidly evolving business landscape, effective communication skills are more critical than ever for managers. Whether you’re a seasoned leader or newly promoted, honing your communication abilities can significantly impact your team’s performance, morale, and overall success. This article delves into three essential communication skills every manager needs to master in 2025 and highlights…

Harnessing the Power of Insights with Quinn Vietnam Manpower

In the dynamic landscape of 2025, where businesses face unprecedented challenges and opportunities, the ability to gain profound insights is more critical than ever. For project management (PM) in Vietnam, this rings especially true. Quinn Vietnam Manpower, a leading provider of manpower solutions, recognizes the crucial role of insights in driving project effectiveness and organizational…