Robotics in Manufacturing: Quinn Vietnam Manpower’s Guide to the Future of Work

- trienkhaiweb

- 26 November, 2024

- 0 Comments

The manufacturing industry is undergoing a transformative shift, largely fueled by the rapid advancements in robotics. This technological revolution is reshaping the way products are made, leading to increased efficiency, enhanced quality, and unprecedented levels of innovation. As a leading force in the workforce solutions sector, Quinn Vietnam Manpower recognizes the importance of understanding and embracing these changes.

The Rising Significance of Robotics in Manufacturing

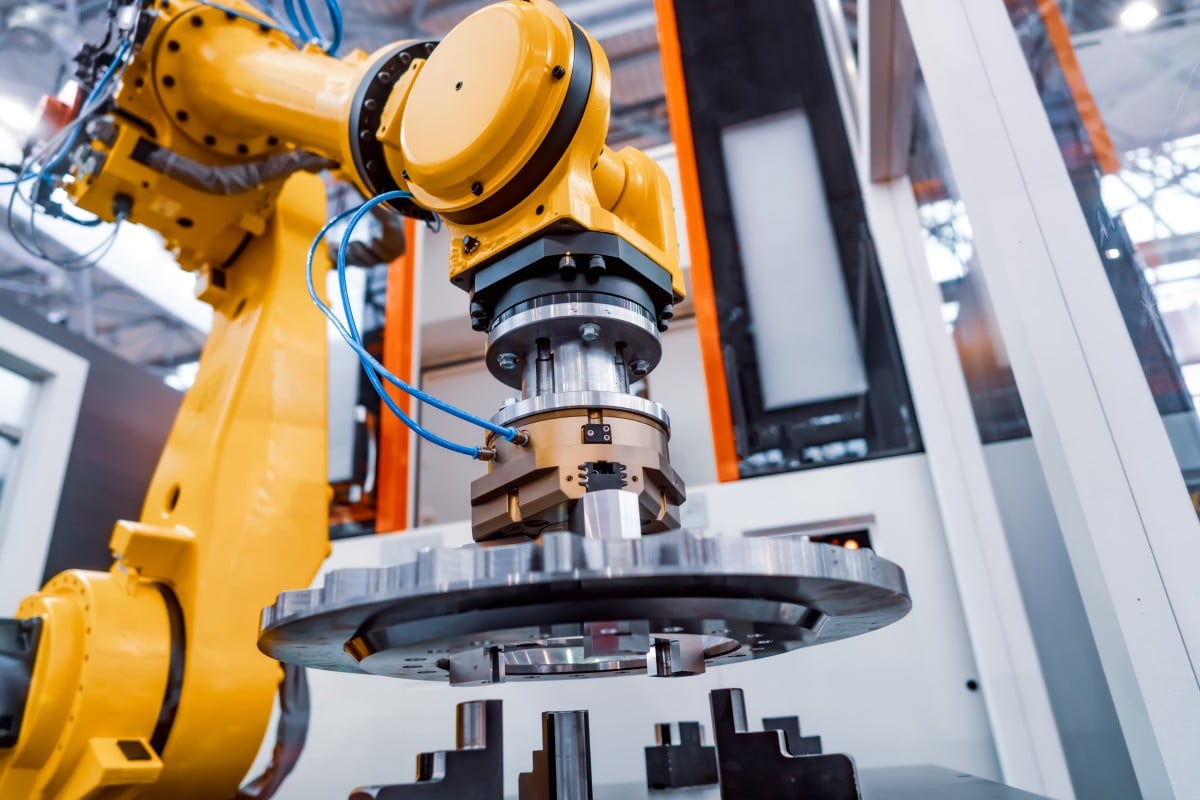

Robotics, the use of programmable machines to perform tasks autonomously or semi-autonomously, has become indispensable in today’s manufacturing landscape. These intelligent machines can handle a broad spectrum of operations, from intricate assembly tasks to rigorous quality control checks.

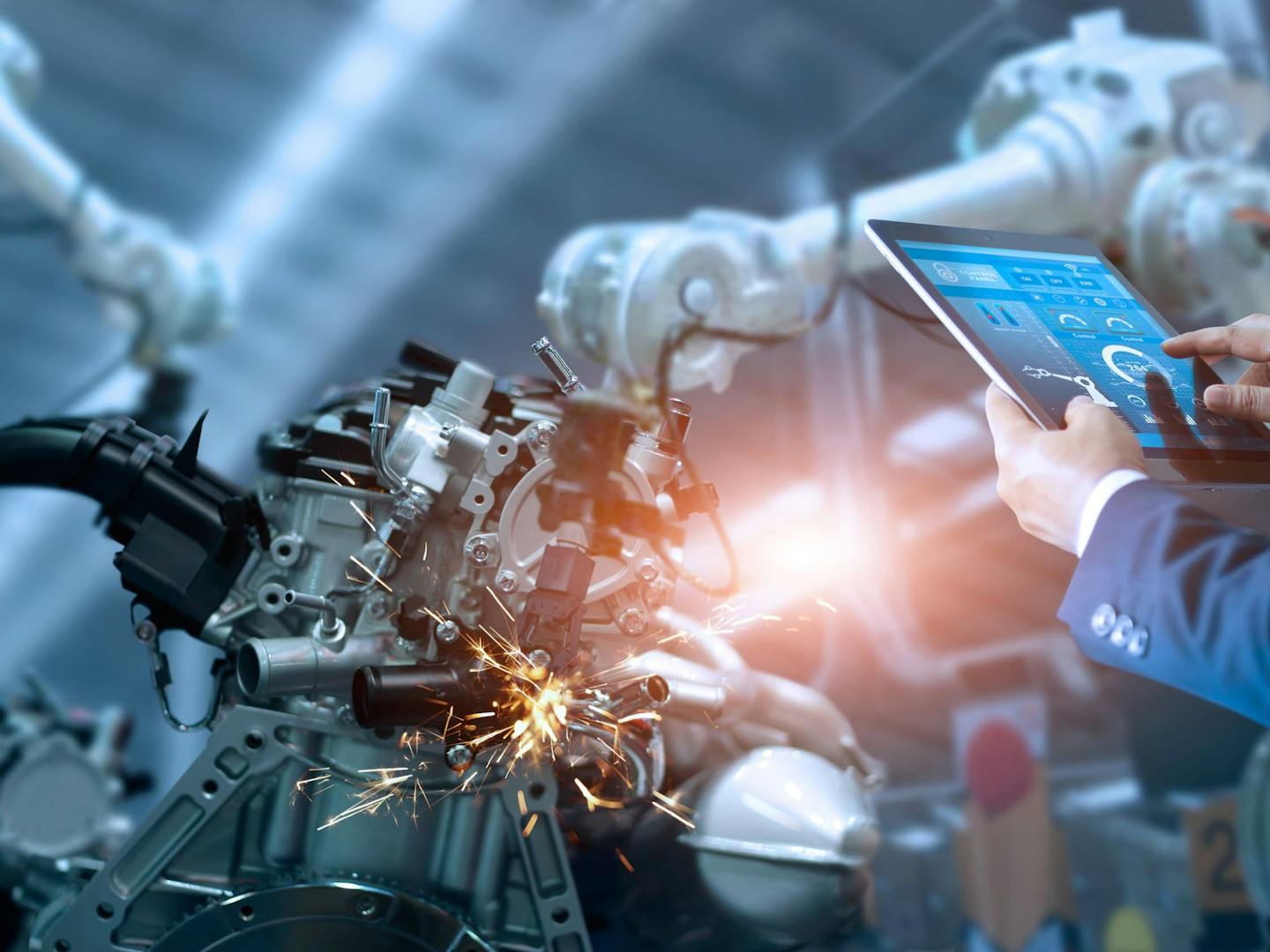

Quinn Vietnam Manpower’s in-depth analysis reveals that robotics is not merely a trend but a fundamental shift in the manufacturing paradigm. By automating repetitive, labor-intensive, or hazardous tasks, robots are freeing up human workers to focus on higher-value activities that require creativity, problem-solving, and decision-making skills.

Exploring the Robotic Workforce: Types and Applications

Industrial robots are the workhorses of modern manufacturing. These specialized machines come in various forms, each designed to excel in specific applications:

- Articulated Robots: The most versatile type, with multiple joints that mimic human arm movement. They are widely used for welding, painting, material handling, and assembly.

- Cartesian Robots: These robots move along linear axes (X, Y, and Z), making them ideal for pick-and-place operations, assembly, and packaging. They are renowned for their precision and repeatability.

- SCARA Robots: SCARA (Selective Compliance Assembly Robot Arm) robots are known for their speed and accuracy in assembly, packaging, and material handling tasks, particularly in the electronics industry.

- Collaborative Robots (Cobots): Designed to work safely alongside humans, cobots are transforming collaborative workspaces. They are often used for pick-and-place operations, assembly, and machine tending.

- Delta Robots: With their parallel arm design, Delta robots are incredibly fast and precise, making them perfect for high-speed pick-and-place tasks in industries like food and pharmaceuticals.

Quinn Vietnam Manpower’s expertise lies in matching the right robotic solution to a manufacturer’s unique needs. Our team of specialists can assess your production line and recommend the most suitable robot types to optimize your operations.

Unleashing the Power of Robotics: Benefits for Manufacturers

The integration of robotics into manufacturing offers a multitude of advantages, positioning businesses for success in the digital age:

Productivity Boost:

- Automation of Repetitive Tasks: Robots tirelessly perform monotonous tasks, freeing human workers to focus on more complex and creative endeavors.

- Reduced Downtime: Robots operate 24/7 without fatigue or breaks, leading to continuous production and increased output.

- Enhanced Speed and Precision: Robots execute tasks with unmatched speed and accuracy, minimizing errors and ensuring consistent quality.

Quality Enhancement:

- Consistent Output: Robots produce uniform products with minimal variation, reducing defects and enhancing customer satisfaction.

- Thorough Inspection: Robots equipped with advanced sensors can meticulously inspect products, identifying even the slightest imperfections.

- Process Optimization: Robots can monitor and control manufacturing parameters like temperature and pressure, ensuring optimal conditions for production.

Cost Reduction:

- Lower Labor Costs: By automating labor-intensive tasks, robots can significantly reduce labor costs over time.

- Increased Efficiency: Robots streamline production processes, minimizing waste and maximizing resource utilization.

- Predictive Maintenance: Equipped with sensors, robots can detect potential issues before they escalate, preventing costly breakdowns.

Quinn Vietnam Manpower: Your Partner in the Robotic Revolution

Navigating the world of robotics in manufacturing can be daunting. Quinn Vietnam Manpower is here to guide you through every step of the process. We offer comprehensive manpower solutions, including:

- Robotic Workforce Assessment: We analyze your operations and identify areas where robotics can deliver the greatest impact.

- Robotic System Integration: We seamlessly integrate robotic solutions into your existing production line, minimizing disruption.

- Robotic Workforce Training: We provide training programs to equip your workforce with the skills needed to work effectively with robots.

The future of manufacturing is undeniably intertwined with robotics. By partnering with Quinn Vietnam Manpower, you can unlock the full potential of this technology and secure a competitive edge in the global market. Let us help you embrace the robotic revolution and propel your manufacturing business to new heights.

Related articles

Employee Empowerment with Quinn Vietnam Manpower

In today’s dynamic business landscape, organizations are increasingly recognizing the importance of employee empowerment as a key driver of success. Quinn Vietnam Manpower, a leading provider of manpower solutions in Vietnam, understands that empowered employees are more engaged, productive, and committed to organizational goals. This article delves into the concept of employee empowerment, exploring its…

Quinn Vietnam Manpower’s 5 Steps to Successful Coaching in 2025

In today’s dynamic business environment, maximizing your manpower’s potential is crucial for success. Effective coaching programs are key to unlocking this potential, fostering employee growth, and driving organizational performance. Quinn Vietnam Manpower, a leading provider of manpower solutions, presents a comprehensive guide to successful coaching in 2025. Whether you’re leading coaching sessions yourself or partnering…

Functional Skills: A Guide for Quinn Vietnam Manpower’s Workforce in 2025

In today’s competitive job market, possessing strong functional skills is more critical than ever. For Quinn Vietnam Manpower, equipping our manpower resources with these essential skills is key to their success and the success of our partner businesses. This comprehensive guide explores the importance of functional skills, particularly in Math and English, and how Quinn…

Level Up Your Workforce: Gamification Strategies for Quinn Vietnam Manpower

In the competitive landscape of Vietnam’s manpower industry, attracting, engaging, and retaining top talent is more critical than ever. Quinn Vietnam Manpower recognizes the power of innovative solutions, and gamification is emerging as a game-changer in the realm of human resources. By integrating game mechanics and elements into various HR processes, Quinn Vietnam Manpower can…

3 Communication Skills Every Manager Needs to Thrive

In today’s rapidly evolving business landscape, effective communication skills are more critical than ever for managers. Whether you’re a seasoned leader or newly promoted, honing your communication abilities can significantly impact your team’s performance, morale, and overall success. This article delves into three essential communication skills every manager needs to master in 2025 and highlights…

Harnessing the Power of Insights with Quinn Vietnam Manpower

In the dynamic landscape of 2025, where businesses face unprecedented challenges and opportunities, the ability to gain profound insights is more critical than ever. For project management (PM) in Vietnam, this rings especially true. Quinn Vietnam Manpower, a leading provider of manpower solutions, recognizes the crucial role of insights in driving project effectiveness and organizational…